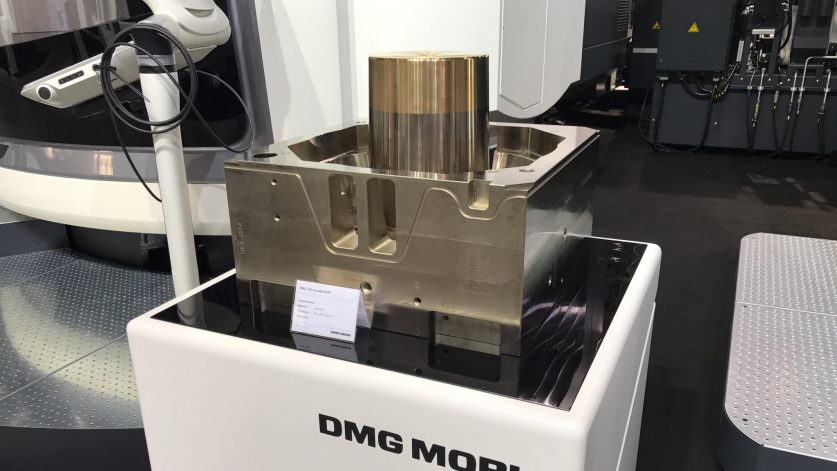

Success at the 2019 K Show, Düsseldorf Germany

Calframax partook in the 2019 K Show in Düsseldorf Germany, the world’s number one trade fair for plastics and rubber. From October 14-26 Calframax showcased our Generation II, high-speed 2 cavity 5 gallon (18.9 litre) pail out of the Krauss Maffei GX 1100-12000 press. With an average cycle time of 13.8 seconds Calframax demonstrated leading...11 / 04 / 2019 BY Marco DiBartolomeo | Feature Post, News